Distribution and fulfillment managers, do you spend valuable time and money fulfilling your customers’ orders, only to find yourself dealing with the same logistics inefficiencies time and time again? These problems only lead to delays in your operations, which create unnecessary costs along the way, and ultimately, what you end up with are unhappy customers.

Here are the issues we’ll be addressing today:

- Congestion and capacity constraints

- Managing revenue recognition processes with multiple customer turnover points

- Lack of predetermined container volumes

If you missed last week’s blog in our Upstream Fulfillment FAQ series, be sure to check it out here.

Take a step toward a more cost-effective and efficient supply chain. See how Upstream Fulfillment can help:

- My current DC is at capacity and my e-commerce business is exploding. How can I create more capacity in my DC without investing millions?

Congestion and capacity constraints in your facilities add unwanted costs and delay filling sales, delivering poor customer experience. Adding additional infrastructure or purchasing new facilities is an expensive and time-consuming process. Organizations should consider whether the productivity of handling all orders in their warehouse outweighs alternative options that still meet customer fulfillment needs and improves productivity.

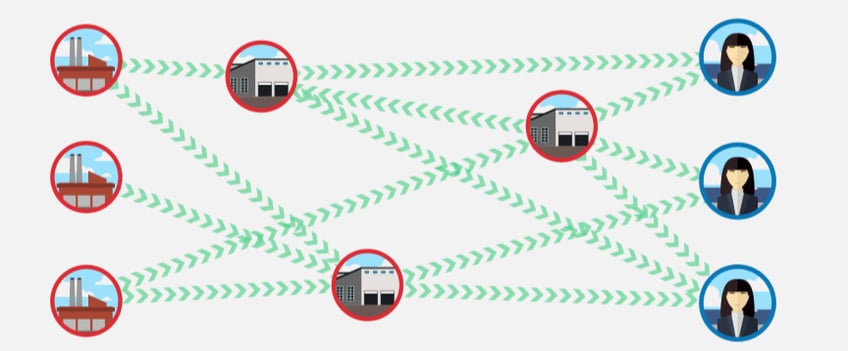

Upstream Fulfillment provides an opportunity to support multiple fulfillment channels from a location nearer to production, eliminating shipping of merchandise to DCs where space is limited. Offloading some percentage of merchandise from your congested facility opens space for fulfillment activities that require shorter lead times and closer proximity to the customer base.

Upstream Fulfillment sites may also pre-process merchandise that require added handling in the DC, such as inspection, labeling, sortation, and Advanced Shipment Notice (ASN) creation, helping improve the receiving efficiency, handling speed, and throughput of the congested facility while still meeting customer demands.

-

How do I control and manage my revenue recognition processes when I have multiple customer turnover points outside of my direct control?

Turning over product directly to your customers at your vendor’s site is a risky and challenging process to manage. With disparate points of sale in countries where you may not have representatives, timely and accurate communication of events can be difficult and create exposure to both revenue recognition policy compliance as well as exposing your vendor purchase details to your end customers.

Upstream Fulfillment provides a single point of accountability, control and data integration for timely and consistent revenue recognition. Additionally, having local resources to ensure the completion of appropriate commercial documents and customer coordination provide an enhanced customer experience while delivering financial compliance.

3. We are unable to receive pre-determined container volumes at the time of purchase order

placement and incur excessive costs as a result. How can we avoid this situation?

Without having information on container volumes beforehand, it allows for excessive transit time, also known as “dwell.” This waiting period often leads to unnecessary demurrage and dwell costs in addition to greater risk to the product being damaged or stolen.

Upstream Fulfillment allocates and releases container quantities after production with less lead time variability. As a result, containers can be metered out to meet actual throughput capabilities, reducing the cost of demurrage and the risk of loss.

Thank you for tuning in to our Upstream Fulfillment FAQ series! For more information on this program and how our solutions can be implemented in your company’s supply chain, don’t hesitate to reach out to one of our representatives.